A leading provider of instrumentation and control systems for the Oil & Gas industry. Silea equips Qwetu Petroleum with advanced measurement and control solutions, contributing to efficient and accurate operations.

TOP LOADING ARM

BOTTOM LOADING AND UNLOADING ARMS

FLOATING SUCTIONS FOR TANKS

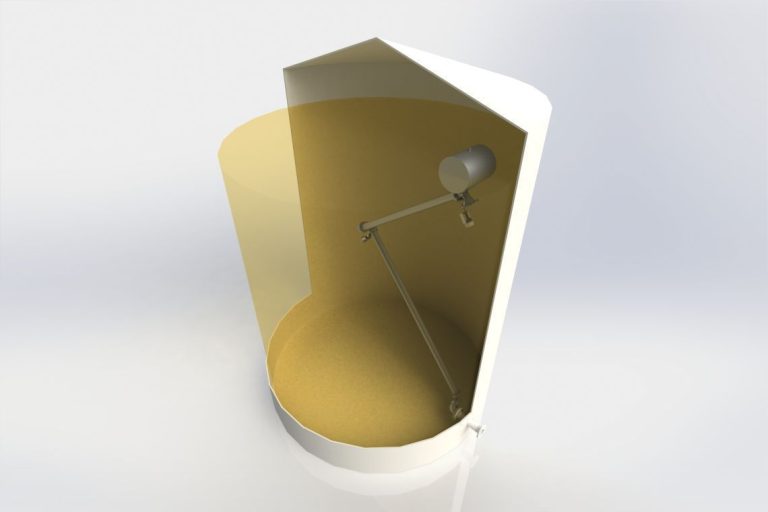

TOP LOADING ARM

Top Loading Arm

The top loading arm is an articulated piping supported by a mechanical balancing (torsion or compression spring) or pneumatic system, which is used to transfer fuels or industrial liquids in tankers and railway tanks through the top manholes.

In particular the series 1050 is designed for road tankers top loading, when the loading position is always at the same distance from the loading rack.

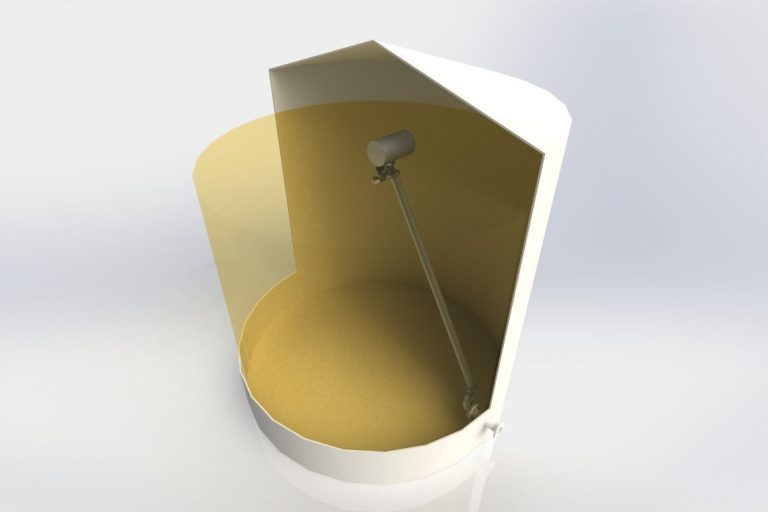

BOTTOM LOADING AND UNLOADING ARMS

Bottom Loading and Unloading Arms

The bottom loading arms are used to load/unload tank trucks and railway tankers for fuels and industrial liquids. This transfer system offers the advantage of operating directly on the ground instead of getting on the tank and thus avoids the formation of electrostatic charges generated. Construction materials range from aluminum alloys and cast iron to special low temperature steels (KCS), stainless (AISI 304 e 316), to respond to the numerous applications in the sectors: Oil&Gas, chemical and food. Same goes for the materials of the seals and gaskets such as: Viton ©(FKM), hydrogenated Buna (HNBR), Karlez ©(FFKM) , Teflon© (ptfe). The application of accessories such as: check valve, break away valve (ERC), ATEX and EAC certified microswitches, for all the control needs of the kinematics during the work phase, temperature and flow sensors, parking devices, stand post. For compliance with the regulations in force applied to the sectors of use of the product, each loading arm is supplied with certificates and declarations of conformity to the ATEX, PED, Machinery directives (if applied), with the use and maintenance manual customized to the product created.

FLOATING SUCTIONS FOR TANKS