Qwetu Petroleum’s in-depth understanding of the African Oil & Gas landscape, coupled with Guidant global engineering prowess, creates a powerful synergy. We can provide our clients with a comprehensive range of services, including:

- Concept engineering and feasibility studies

- Front-End Engineering Design (FEED) packages

- Detailed engineering and design

- Procurement and construction services

- Project management and execution

- Commissioning, start-up, and operational support

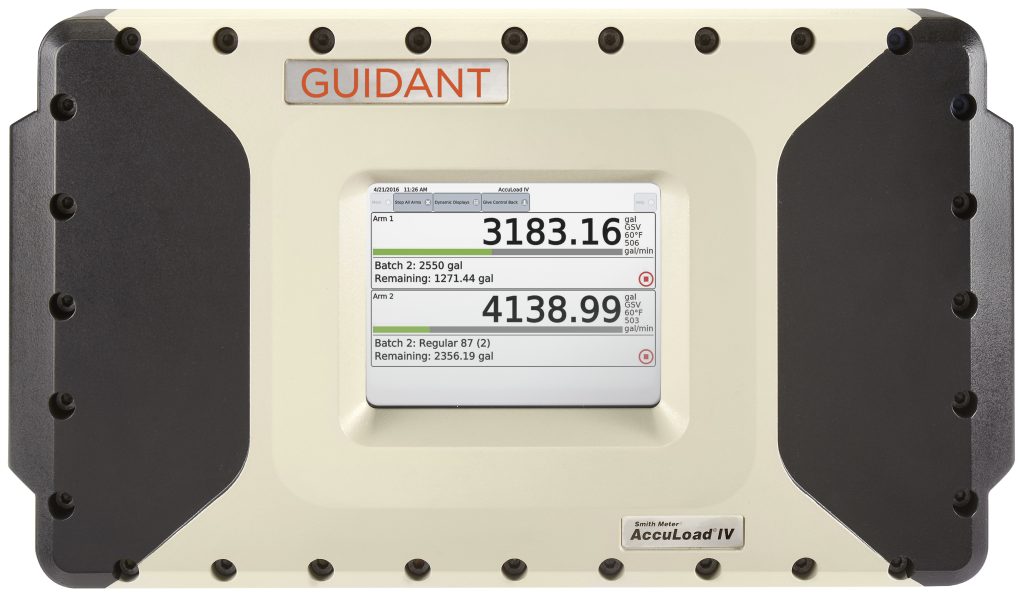

Single Touch Screen (ST)

Explosion-proof enclosure

Two-arm operation

Up to four single- or dual-

pulse product meter inputs

Up to four additive-meter

inputs

Up to 24 additive-meter

inputs with A4I module

AccuLoad III to IV Upgrade Kit (UG3)

Quad Touch Screen (QT)

Up to six-armoperation

Up to six single- or dual-pulse product meter inputs

Up to four additive-meter inputs

Up to 24 additive-meter inputs with A4I module

AccuLoad III to IV Upgrade Kit (UG3)

NEMA 4 (N4)

One- or two-arm operation

Up to four single- or dual- pulse product meter inputs

Up to four additive-meter inputs with local I/O

Up to 24 additive-meter inputs with remote A4I module

Stainless steel enclosure

Integrated card reader, indicator lights, and stop button options

Split Architecture (SA)

Up to eighteen-arm operation

Up to 24 single- or dual- pulse product meter inputs

Up to 56 additive-meter inputs with A4I module

Up to 96 additive-meter inputs with remote A4I module

Integrated card reader, indicator lights, and stop button options on the man-machine interface (MMI)

AccuLoad III to IV Upgrade Kit (FMU)

PD Meter – prime 4

The Smith Meter PRIME 4 meter is a 4-inch, single-case, positive-displacement meter designed for maximum accuracy and reliability. The PRIME 4 meter is ideal for loading-rack service and custody transfer of petroleum products.

Applications include gasolines and oxygenates, ethanol, kerosene, diesel fuel, jet fuels, and fuel oils.

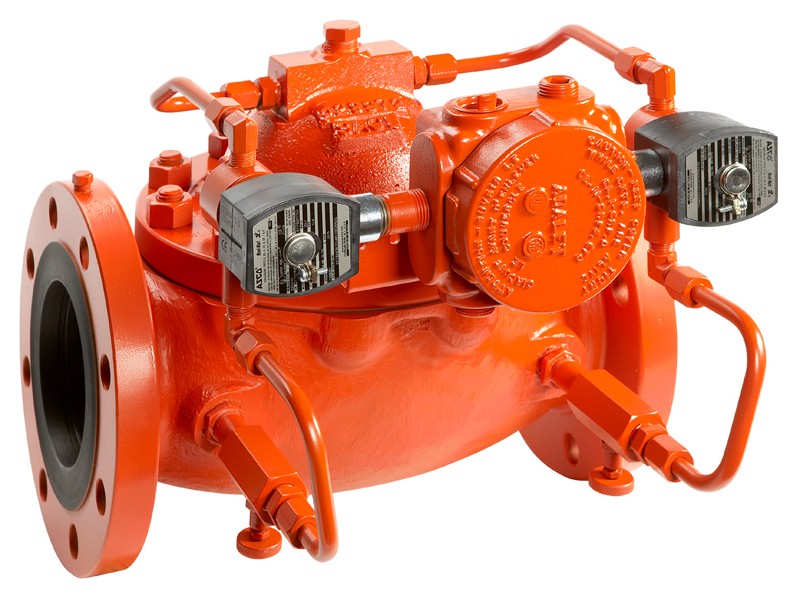

Smith Meter® Model 210 Digital Electro-Hydraulic

The Smith Meter® Model 210 Valve fundamentally consists of a Smith Meter® 200 Series Valve with two solenoid controls. A valve response control device, typically a needle valve, is located between each solenoid and its respective upstream or downstream port.

Pipeline Strainers

Metering system components require protection against the damage potential of dirt and debris. Smith Meter® Pipeline Strainers provide this protection for 4″ and larger turbine and positive displacement meter applications.

FuelFACS Terminal Automation System

Guidant ’s end-to-end terminal management solution for measurement, accounting and control allows customers to manage and optimize all their facilities from one single integrated interface. Our terminal management systems are based on Guidant ’s scalable FuelFACS™ and smart, reliable measurement equipment; improving terminal throughput, increasing premises and data security and providing traceable and accurate measurement data.

Along with excellent global support, our solutions can be applied to marine, pipeline and terminal applications to help you understand the health of your facilities and optimize the transportation and storage of energy products across the downstream value chain for faster and safer product delivery.